APPLICATIONS

There are multiple applications where friction welding offers advantages over conventional solutions. Combining materials, achieving stronger welds and reducing labor costs. Do not hesitate to contact us if you have any questions about whether your product is suitable for friction welding.

Diameter: <135 mm

Length: <3500 mm

Chrome layer: min 20um or according to customer's requirements

Surface roughness: Ra <0.2um

READY-TO-ASSEMBLY

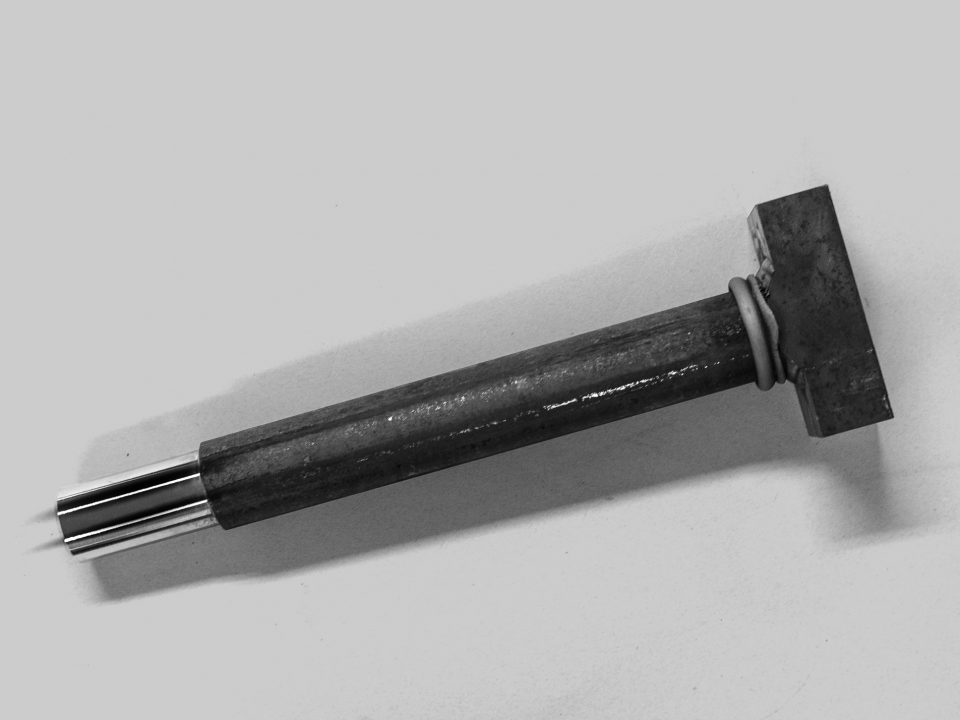

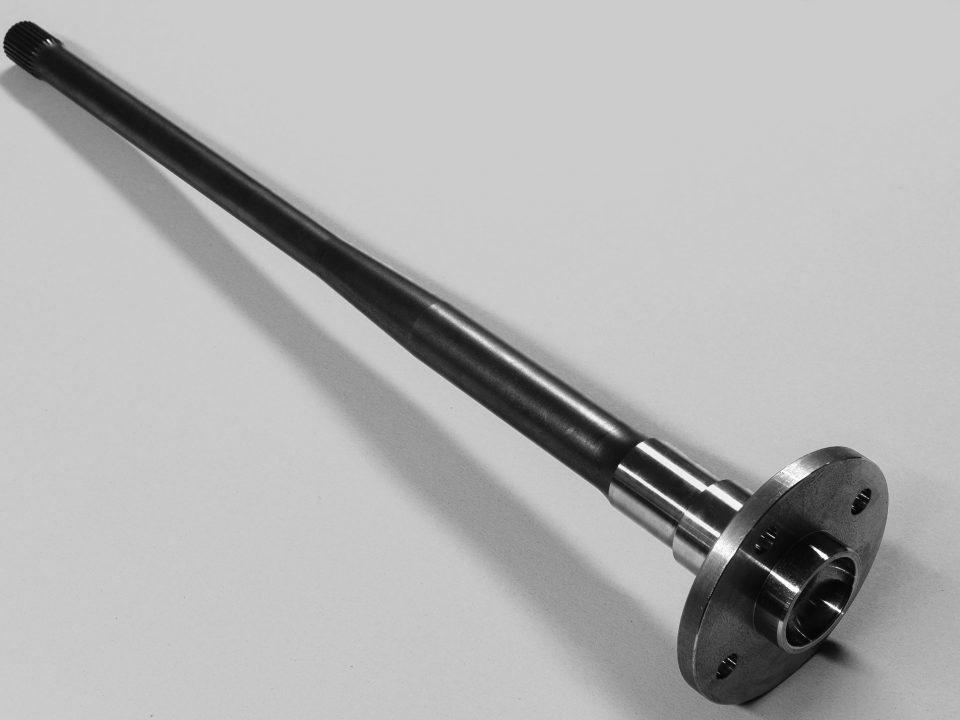

PISTON BARS

Ready-made piston rods contribute to major savings in the manufacture of hydraulic cylinders. A rational machinery park manufactures competitive, assembled piston rods. A careful quality control means that the piston rods can be taken directly to the final assembly.

Friction welded eyelets givse the piston rod maximum strength and the joint has the same strength as the base material. Rolling threads also give the rod the highest possible strength, which extends the life of the piston rod. Induction-hardened rods and chrome layer provides the best possible wear protection and ability to withstand bumps and blows. With Fricweld's method, we enable the chrome layer to be placed closer to the joint, which among other things gives shorter cylinder dimensions. Ultrasound testing is performed according to the customer's specifications.

MATERIAL

MATRIX

Download our material matrix showing combinations of materials welded with friction welding. Other combinations are also possible. Please contact us for further information!

THE BENEFITS OF FRICTION WELDING

Friction welding is a cost-effective process that provides higher quality, is more environmentally friendly and enables more material combinations compared to traditional welding methods.

SOLUTIONS

Our partners, strong supplier base, production and efficient, flexible logistics offer very cost-effective comprehensive solutions from sourcing to delivery.